Home

A Packaging Format's Journey

Collaboration is Essential

Elements of Recyclability

CircularityinAction.com

Recycling Education

BagandFilmRecycling.org

RecycledProductsDirectory.org

PlasticsMarkets.org

Info Exchange

Plastic Recycling Terms & Tools

Sort for Value Calculator Collaboration Is Essential for Recycling

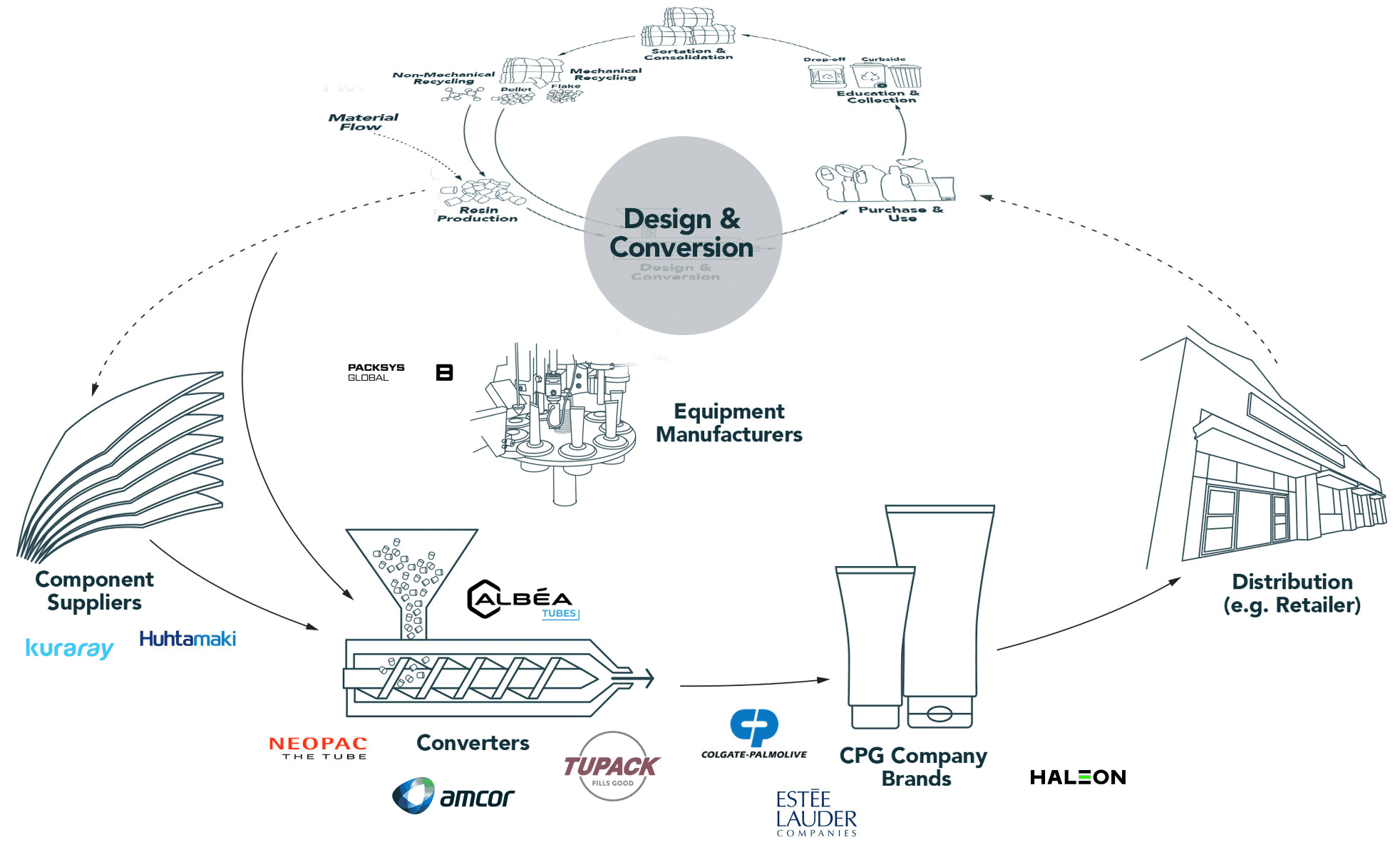

Recycling Requires Everyone to Do Their Part Successful recycling functions best when supply and demand are in balance and can drive innovation, investment, collaboration, and participation. Brands and manufacturers, packaging converters, recycling programs, consumers, equipment and components suppliers, and recyclers all have a role to play. Facilitating collaboration and ensuring stakeholder engagement is how we can work through the barriers and realize solutions on the path to recyclability and ultimately, circularity. Working together is essential.

We All Have a Part to Play in These Actions that Drive Recycling

How the Collaboration Started In 2015, the US Tube Project started and began to harness collaborative thinking to work with engaged companies, recycling organizations, and other stakeholders to provide the data and information needed to understand the barriers and work through solutions to make plastic squeeze tubes, as a packaging format, accepted for recycling. The project kicked off with a focus on whether or not reclaimers could recycle tubes with an existing stream (of value in the marketplace) and if there were concerns to overcome. Several years later, the European project kicked off to work concurrently on recyclability. The efforts focus on how to maximize recycling of valuable material (recyclable plastic tubes) and minimize contamination to the recycling system.

Collaborative Thinking Drives Progress In order to have clear communication to consumers and minimize contamination in the recycling stream, it is essential that not only an individual package, but the majority of the packaging format on the market be converted to designs compatible for recycling. For most packaging formats, individual companies dont have enough market share to make this conversion alone. The Tube Recycling Projects highlight what is possible when competitors do work together to make significant progress on long-term shared goals, such as making a packaging format like squeeze tubes recyclable.

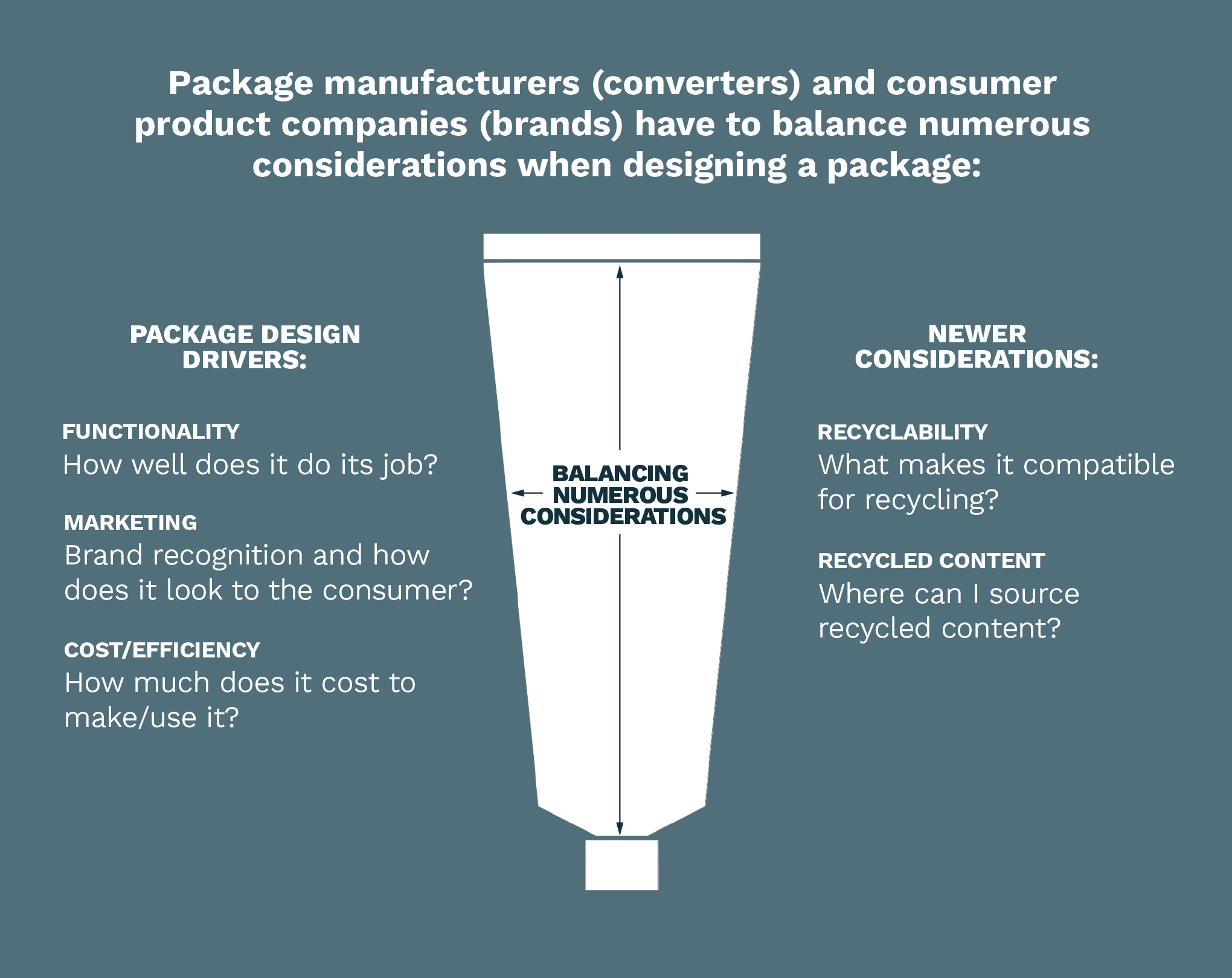

Ultimately, making a recyclable package may require rethinking business as usual as we balance the various design drivers. There are some tradeoffs; for example, some decorations used for marketing purposes or barrier layers used to preserve the product may be at odds with recyclability. However, brands and converters have been able to assess packaging requirements and use innovation to balance the design drivers to make progress to achieve recyclable tubes. The Tubes Recycling Projects showed that collaboration is essential to making progress in making more recyclable packages. For example, component makers and converters have created recycling compatible layers, closures, and tube bodies; equipment manufacturers have made equipment adjustments to run new recyclable materials; and brands have committed to putting the new designs on the shelves. All of these organizations must understand the recyclers' perspective and coordinate innovation across the supply chain to achieve better design for recycling. Stina would like to acknowledge the project funders: Amcor, Colgate-Palmolive, Haleon, Kenvue, Procter & Gamble, and other companies and organizations that have supported this effort along the way.

Project Collaboration is Essential

Collaboration at All Levels Broad, industry-wide collaboration has been needed to fully understand needs and leverage successes to move plastic squeeze tubes, as a packaging format, towards recyclability and acceptance for recycling. Companies with a common interest (often competitors) have to work together and across the value chain with recyclers and MRFs to understand barriers and opportunities. Stakeholder organizations at the regional or national level work with companies to provide support and guidance across borders to align efforts. At its best, this collaboration moves all parts forward, closer to achieving the shared goals for recyclability, recycling, and use of recycled content. The Association of Plastic Recyclers (APR) Tube Design Working Group was a great example of industry collaboration. The working group was formed in 2019 and focused on providing design consideration guidance for plastic squeeze tubes. The group went on to recommend a Plastic Squeeze Tubes Design Resource Document that APR released in August 2020. This resource continues to be updated as new information is available. The Tubes Recycling Projects support continued alignment efforts between APR and RecyClass.

Collaboration at All Levels Broad, industry-wide collaboration has been needed to fully understand needs and leverage successes to move plastic squeeze tubes, as a packaging format, towards recyclability and acceptance for recycling. Companies with a common interest (often competitors) have to work together and across the value chain with recyclers and MRFs to understand barriers and opportunities. Stakeholder organizations at the regional or national level work with companies to provide support and guidance across borders to align efforts. At its best, this collaboration moves all parts forward, closer to achieving the shared goals for recyclability, recycling, and use of recycled content. The Association of Plastic Recyclers (APR) Tube Design Working Group was a great example of industry collaboration. The working group was formed in 2019 and focused on providing design consideration guidance for plastic squeeze tubes. The group went on to recommend a Plastic Squeeze Tubes Design Resource Document that APR released in August 2020. This resource continues to be updated as new information is available. The Tubes Recycling Projects support continued alignment efforts between APR and RecyClass.

From Collaboration to Recyclability

To ensure plastic squeeze tubes, as a packaging format, can be recycled, it is essential that tubes are: • Designed for recycling, so they are compatible and acceptable by recycling markets that can process them into recycled feedstock, • Able to be captured by infrastructure that can consolidate them into a recycling stream so it can be delivered to recycling markets, and • Accepted and collected for recycling by programs, so individuals know they can recycle them.

As the Tubes Project finalizes the remaining steps on this recyclability journey, Stina will continue to support organizations like APR and RecyClass, the Institute of Scrap Recycling Industries (ISRI), the Tube Council, and others in engagement and communication with the value chain to advance tube recycling.

As the Tubes Project finalizes the remaining steps on this recyclability journey, Stina will continue to support organizations like APR and RecyClass, the Institute of Scrap Recycling Industries (ISRI), the Tube Council, and others in engagement and communication with the value chain to advance tube recycling.

Learn more about the journey of plastic squeeze tubes.

To Dig Deeper:

A Packaging Format's Journey View

Elements of Recyclability View

Home

Managed by Stina Inc.

Connect with us on:

Connect with us on:

©2026 Stina Inc. All rights reserved. Terms & Conditions